Commitment towards a lower environmental footprint

Certificates

Long lasting design

The right design process allows for long-lasting products due to the right use of materials and easy assembly which translates into less installation time while also avoiding damages during the installation, this also equates to a reduction in after-sale issues and avoids unnecessary re-deliveries.

Our commitment to continuously guarantee long-lasting products contributes positively to the use of only necessary resources and materials.

Sustainable production and technology

The manufacturing process of .mdd products takes place in the factory located in Sepolno Krajenskie, Poland. The factory has recently undergone continuous investments in machinery and technology, which has been crucial in the development of new products, resulting in the ability to control and adapt to sudden changes that may arise. This investment also translates into using only the necessary transport of the raw materials to the factory and then to the client, instead of additional transport which would otherwise be used when outsourcing work, meaning a reduction in the use of fossil fuels.

The use of optimal fabric lamination technology and cutting technologies with machines like the Cutter, has significantly lowered the volume of the material waste and the amount needed to manufacture the goods. Our painting line is a method of powder coating that works at the highest speed possible while ensuring accuracy and quality in the final result. The procedure is set to collect and recycle spill of powder coat, limit the exposure of toxic fumes, and re-use the heat produced during this process to be later re-purposed.

By using new machinery, the production complies with the highest energy usage standards, with an energy-saving mode prompting the systems into a “suspension” mode when not in use.

Reliable sources

The use of only domestic and European suppliers ensure high-quality material and minimum impact on the environment.

The main subjects of that distribution are ready parts, components and predominantly upholstery fabrics. We make an effort not only to manage our supply chain in a sustainable way, but also to include ecological textiles in our offer. One of them is Mica, almost entirely recycled. 97% of the polyester used in its production comes from post-consumer recycling. Also Kvadrat's Field and Gabriel's Go Check are environmentally friendly choices. Made of 100% Trevira CS, they hold a few sustainability certificates, such as the EU Ecolabel, Oeko-Tex® Standard 100, Greenguard and Greenguard Gold. Last, but not least, the Vita eco-leather contributes to the positive climate change, as it is an animal friendly alternative to the traditional material.

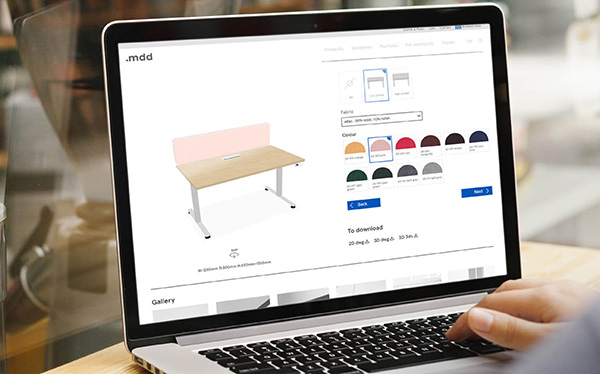

Digitalisation

.mdd has prominently focused on the increase of digitalisation, especially in the marketing sphere. A significant decrease in paper usage has been shown by bringing to an end the production of printed copies of brochures, price lists and other supportive material. This initiative has been put in place, as well as introducing an advanced online configurator and the availability to download important material through the website. This has benefited the client positively given that the access to the latest information is at their fingertips, this results in the possibility to use less of their physical storage space and the peace of mind of not having to carry heavy material around.

The introduction of QR codes labelled on the carton boxes allowed .mdd to utterly terminate further printing of paper manuals.

Eco packaging

All .mdd products are delivered in parts, meaning each part is flat-packed ensuring quality upon arrival; this reduces the volume used per vehicle, providing the opportunity to host a larger quantity of products to be loaded on a single lorry. In 2020, .mdd decided to use honeycomb paper panels instead of Styrofoam; paper can be easily recycled which lowers the negative impact on the environment.

The paper and/or cardboard has 100 % post-consumer material. The company is constantly investing efforts on increasing the levels of recycled plastic usage, currently, part of the plastic being used in packaging has post-consumer material.

Utilizing the carton box making machine, .mdd is capable of producing custom size packaging for all its products, reducing the use of paper and increasing the amount of load carried by a single lorry.

Optimised transport

Currently, the increasing levels of CO2 in the environment due to the number of vehicles are one of the biggest causes of pollution. Around one-quarter of these vehicles circulating worldwide happen to be lorries, which is why .mdd invests efforts in optimising each delivery route once products leave the factory. Our logistics technology allows different configurations and monitoring of traffic flow for efficient routes in order to reduce mileage, fuel consumption and the number of lorries needed to deliver the products worldwide.

The absence of third-party logistics means a more straightforward approach when planning; the products are delivered directly to the customer, reducing not only timings but extra fuel used if third parties were involved.

Social responsibility

For .mdd, taking care of the local community is equally as important as caring for the environment. The company makes an effort to be socially responsible, regularly engaging in charity campaigns. Especially those that focus on helping local residents and supporting organisations in the region. If only it is possible, .mdd takes actions aimed at supporting its employees and their families. Such actions take various forms, from product donations to fundraising, but they all contribute to improving the quality of life in the immediate neighbourhood of the company.

Environmental compliance

.mdd complies with ISO-14001 and ISO-9001 certificates, prompting the company to constantly improve in matters related to quality, safety, and environment.

All .mdd products have been checked for environmental and health regulations. No forbidden hazardous chemicals (in accordance to REACH) have been used during the production process, guaranteeing it's safe to use.

The category E1 means that these boards are categorised in the low E1 class for formaldehyde stated and thereby meet the current requirements across Europe.

Raw materials and components are bought in Europe with CE marking and others, ensuring European standards for health, safety and hygiene, as well as sustainable compliance.

The Environmental Product Declaration is the overview of the product following the rules and principles outlined in EN ISO 14025 and 14040 that states thorough information about the environmental impact of the product's entire lifecycle.

.mdd meets the requirements of the more and more environmentally conscious world and complies with the standards of modern procurement in public and private sectors.

Currently, the EPD cards feature the entire OGI line-up, with more items to come in the nearby future.

ISO certificates:

- EN ISO 9001:2015;

- PL ISO 9001:2015;

- EN ISO 140001:2015;

- PN-N-18001:2004

Product certificates:

- Environmental Product Declaration Type III ITB No. 267/2021. Conference tables

- Environmental Product Declaration Type III ITB No. 266/2021. Office desks

- Test of volatile organic compounds (VOC) emission by the chamber method according to PN-EN ISO 16000-9

Responsible from start to finish

The company is responsible for providing high quality and durable products from European sources, this is the result of years of research and product development including in-house tooling and prototyping which reduces timings and transport in the development of most products, meaning fewer fossil fuels. Transport, production, power and waste management is optimised in compliance with .mdd's sustainable vision in accordance with project priority and feasibility.